V-Belts Families

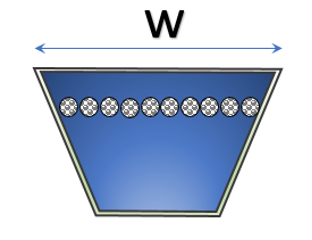

Classic belts

This is the most common type of V belts. They are commonly used in agricultural applications and industrial machinery.

They have a good temperature resistance (-31F to 158F) but a limited resistance to oil.

The way they are measured is with the top width and the internal length (in inches). Depending on the width there are 5 types of classic v belts:

Classic A : ½” top width

Classic B: 21/32” top width

Classic C: 7/8” top width

Classic D: 1 ¼” top width

Classic E: 1 ½” top width

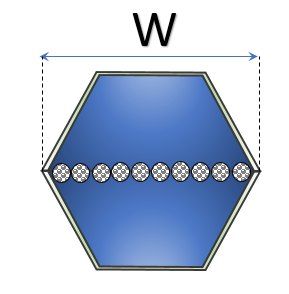

Double sided Belts

They are used on applications where power transmission is needed in both sides of the belt. They are commonly used in textile and industrial applications.

They have a good temperature resistance (-31F to 158F) but a limited resistance to oil.

The way they are measured is with the width of the cross section center (midpoint) and the internal length (in inches). Depending on the width there are 3 types of double sided belts:

Double Side AA: ½” center width

Double Side BB: 21/32” center width

Double Side CC: 7/8” center width.

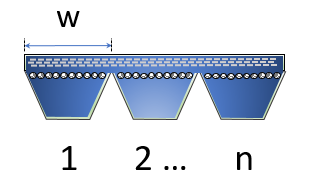

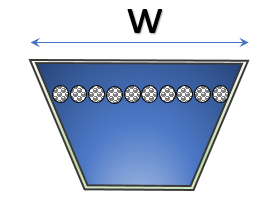

Banded Belts

They are used by original equipment manufacturers in applications where the pulley design requires two or more v belts joined together to connect multiple pulley drives avoiding load fluctuations or belt turn over.

They have a good temperature resistance (-31F to 158F) but a limited resistance to oil.

The way they are measured is by the number of bands, the width of each band and the internal length. Depending on the width ad if they are cogged there are 9 types of banded belts:

Banded A: ½” width

Banded B: 21/32” width

Banded C: 7/8” width

Banded D: 1 1/4” width

Banded 3V: 3/8” width

Banded 5V: 5/8” width

Banded 8V: 1” width

Banded Cogged 3VX: 3/8” width

Banded Cogged 5VX: 5/8” width

Cogged Belts

They are used in applications with small pulley diameters and high speeds. The slots on the belt reduce the bending resistance and keep operation temperatures lower.

They have a good temperature resistance (-31F to 158F) but a limited resistance to oil.

The way they are measured is by the top width of the belt and the internal length. Depending on the width there are 6 types of cogged belts:

Cogged AX: ½” width

Cogged BX: 21/32” width

Cogged CX: 7/8” width

Raw edge Cogged 3VX: 3/8” width

Raw edge Cogged 5VX: 5/8” width

Raw edge Cogged 3VX: 1” width

Metric Belts

They are used in industrial applications like fan belts, vacuums, and printing industry. They can transmit 1.5 to 2 times more power than classical belts.

They have a good temperature resistance (-31F to 158F)

The way they are measured is by the top width of the belt and the internal length. Depending on the width there are 4 types of metric belts:

Metric SPZ: 10 mm width

Metric SPA: 13 mm width

Metric SPB: 17 mm width

Metric SPC: 22 mm width

Automotive Belts

They are designed mainly for the automotive industry where pulley diameters are very small, belt speeds are very high, power transmission demand very high and there are elevated operation temperatures.

They have a good temperature resistance (-31F to 158F) and resistance to oil.

The way they are measured is by the top width of the belt and the internal length. Depending on the width there are 4 types of automotive belts:

Automotive 15: 15/32” top width

Automotive 17: 17/32” top width

Automotive 22: 22/32” top width

Automotive 28: 28/32” top width

Fractional Wrapped Belts

They are designed mainly for low horse power applications that require a lower maintenance because of the operation conditions like oil, dust and high temperature. Some of the most common applications are low HP diesel engines, processing machines, pumps, mining, compressors saw and milling.

They have a good temperature resistance (-31F to 158F) and resistance to oil.

The way they are measured is by the top width of the belt and the internal length. Depending on the width there are 3 types of fractional wrapped belts:

Fractional 3L: 3/8” width

Fractional 4L: ½” width

Fractional 5L: 21/32” width

Wedge Wrapped Belts

They are ideal for applications with high HP demand in presence of oil and high temperatures.

They have a good temperature resistance (-31F to 158F) and resistance to oil.

The way they are measured is by the top width of the belt and the internal length. Depending on the width there are 3 types of wrapped belts:

Wrapped 3V: 3/8” width

Wrapped 5V: 5/8” width

Wrapped 8V: 1” width

Kevlar / Aramid Belts

Aramid belts are designed for some of the most demanding applications where high resistance against oil, grease, dirt and moisture is requires. The most common applications are mowers, aerospace and military applications.

They have a good temperature resistance (-31F to 158F) and resistance to oil, grease and moisture.

The way they are measured is by the top width of the belt and the internal length. Depending on the width there are 7 types of Kevlar belts:

Fractional Kevlar 3L: 3/8” width

Fractional Kevlar 4L: 1/2” width

Fractional Kevlar 5L: 21/32” width

Kevlar A: 1/2” width

Kevlar B: 21/32” width

Kevlar C: 7/8” width

Kevlar 3V: 3/8: width

If you need help identifying the type of belt you need you can always call us and one of our power transmission specialist will help you.